Before and After

Repair done on Backflow and Stop N Waste

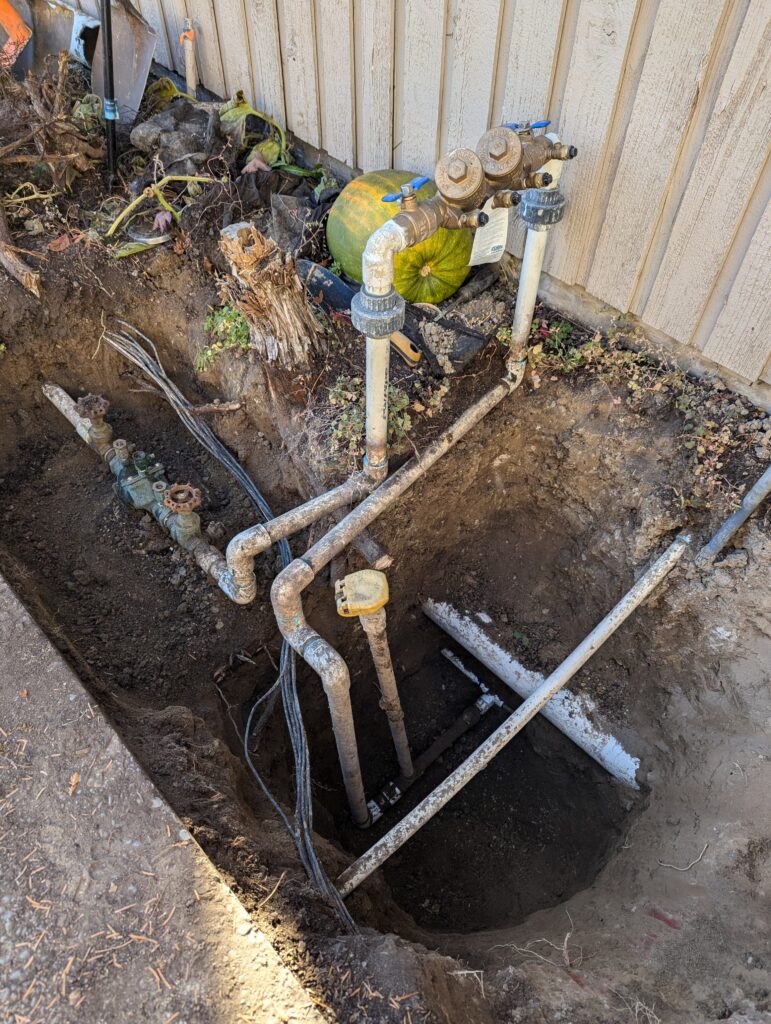

These are images of a before and after that I had done for a customer. The old system had two backflows and you’re only supposed to have one. The quick connect blowout was connected right after a brass 90 degree brass ball valve which is not a turn on that is appropriate for when needing the water off for the winter. The customer called because the water was not turning off and they needed a blowout. The corroded valve was stuck half way on when handle broke off. Last contractors placed the new backflow above ground coming off existing mainline before old backflow. That’s not the way to do that.

I reduced the ten 90’s down to just two and placed the new backflow where the old backflow was inside the box underground. A Ford stop n waste was added along with a blowout after the backflow. FYI I never disturbed the melon.

This is the best and most accurate way to get the best water pressure.